When it comes to choosing the right rivet nut for your application, it's generally recommended that if manufacturers and assemblers can create a hexagonal hole, using a hex body rivet nut is the most effective way to secure joints together. This type of rivet nut excels at resisting spin-out, making it a top choice for applications where torque resistance is critical.

However, what happens when you're dealing with automated fastening systems? Is the hex body rivet nut still the best option when installing rivet nuts automatically through an automation system? Probably not—especially now that Optisert rivet nuts are available. While high-volume installations often rely on automation due to its speed, precision, and efficiency, the process becomes more challenging when working with hexagonal holes for hex body rivet nuts. Automation feeders require precise alignment between the rivet nut’s hex points and the corresponding hole, which can be costly and complex to achieve with standard automation equipment.

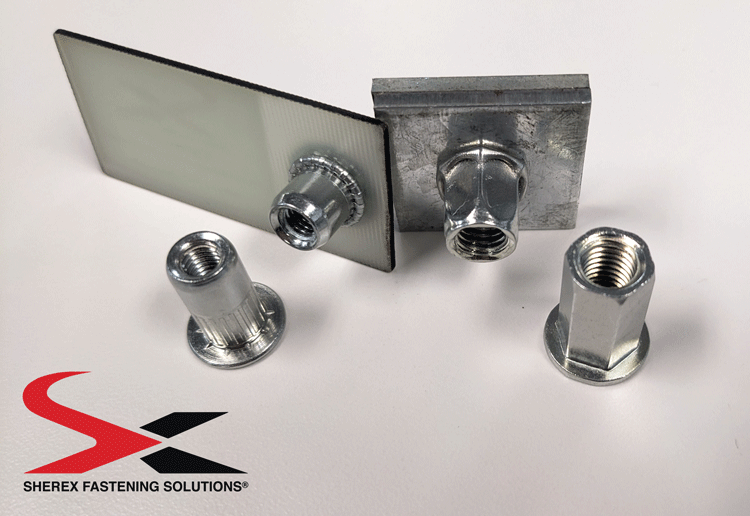

Optisert vs. Hex Body Rivet Nut

In contrast, using a round body rivet nut with a round hole simplifies the installation process significantly. There’s no need to worry about aligning specific points since both the rivet nut and the hole are symmetrical. For high-volume automated setups, this simplicity translates directly into cost savings and operational efficiency.

Now, let’s talk about performance. Hex body rivet nuts are indeed superior when it comes to resisting spin-out. However, Optisert rivet nuts come surprisingly close in terms of performance, especially in softer materials such as plastics, composites, and aluminum. Their strength metrics rival those of half-hex body rivet nuts and even approach the levels achieved by full hex body rivet nuts in certain applications. On top of that, Optisert rivet nuts are typically more affordable than their full hex counterparts.

Given these considerations, when deciding between full hex rivet nuts and round body rivet nuts for automated systems, performance may not always be the primary factor. Instead, ease of installation and compatibility with the automation system often take precedence. In this context, Optisert rivet nuts stand out as a strong contender. They offer performance comparable to hex body rivet nuts while maintaining the simplicity and efficiency of round body rivet nuts. As a result, Optisert rivet nuts could very well represent the optimal solution for automated rivet nut installations in today’s manufacturing landscape.

Of course, every application has unique requirements, so it’s essential to evaluate each situation carefully before making a final decision. Whether you prioritize maximum torque resistance, cost-effectiveness, or streamlined automation processes, understanding the trade-offs between different types of rivet nuts will help ensure the best possible outcome for your project.

Ultimately, the choice between hex body rivet nuts and Optisert rivet nuts depends on balancing performance, cost, and practicality. If your primary concern is automating the installation process efficiently without sacrificing too much strength, Optisert rivet nuts deserve serious consideration. After all, modern manufacturing demands solutions that strike the right balance between innovation, affordability, and reliability—and Optisert seems to deliver just that.

So whether you're looking to improve production speeds, reduce costs, or enhance overall quality control, exploring the benefits of Optisert rivet nuts could prove invaluable. As industries continue to evolve toward greater automation, finding ways to simplify and optimize assembly processes will remain key priorities. And with tools like Optisert leading the charge, the future of fastener technology looks brighter than ever.

Vibrating plate compactors are mainly suitable for materials with less cohesion and friction between compacting particles, such as river sand, gravel and asphalt. The main working parameters of the vibrating plate compaction are: the bottom area of the working plate, the mass of the whole machine, the excitation force and the excitation frequency. Under normal circumstances, the bottom plate area of the same type of plate is about the same, so the performance of the plate rammer is mainly affected by the quality, excitation force and excitation frequency of the whole machine. The excitation force is mainly used to maintain the forced vibration of the tamped material; The excitation frequency affects the tamping efficiency and compaction degree, that is, under the same excitation force, the higher the excitation frequency, the higher the tamping efficiency and compactness.

Plate Compactor Machine,Forward Type Plate Compactor,Road Plate Compactor,compactor vibrator

Vibropac Machinery Co.,Ltd , https://www.vibropac-power.com