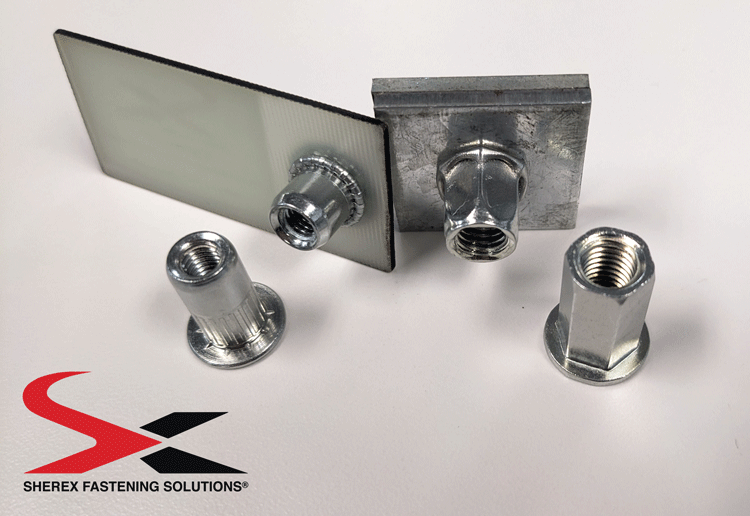

When it comes to joining components together, it's widely recommended that if your manufacturing process allows for creating a hexagonal hole, using a hex body rivet nut is the optimal choice. This approach provides excellent resistance to spin-out, ensuring a secure connection between parts.

However, what happens when you're working within a fastener automation system? Is the hex body rivet nut still the best option for automated installations? Not necessarily. Especially with the advent of Optisert technology, which has revolutionized the way we approach rivet nut installations.

In high-volume production environments, automation is often the most efficient method for installing rivet nuts. It's faster than manual labor, ensures consistent quality, and eliminates the need for human intervention. Yet, when integrating hex body rivet nuts into an automated system designed for hexagonal holes, challenges arise. The feeder mechanism must precisely align the rivet nut’s hexagonal shape with the corresponding hole—a task that requires advanced and costly machinery.

On the other hand, using a round body rivet nut with a round hole eliminates these alignment issues entirely. Since both the rivet nut and the hole lack sharp edges, there’s no need for precise orientation during installation. This simplicity makes the round body rivet nut a more practical choice for automated systems, especially when paired with cost-effective equipment.

Now, what about performance? While hex body rivet nuts excel in resisting spin-out, Optisert has proven itself as a strong contender. In certain applications—such as those involving softer materials like plastics, composites, or aluminum—Optisert's performance closely matches that of full hex body rivet nuts. Moreover, Optiserts are typically more affordable than their hexagonal counterparts.

For companies focused on automating rivet nut installations, ease of integration should take precedence over performance metrics. After all, the primary goal of automation is to streamline operations and reduce costs. Given that Optisert offers performance comparable to hex body rivet nuts while maintaining the simplicity of a round body design, it stands out as one of the best options available today for automated assembly lines.

So, the next time you're weighing whether to use full hex rivet nuts or round body rivet nuts for your automated processes, remember that performance isn't always the deciding factor. Instead, prioritize solutions that make your automation system run smoothly and efficiently. With Optisert's balance of affordability, ease of use, and impressive performance, it could very well be the ideal solution for your needs. ---

Vibrating ruler or surface finishing screed is a commonly used tool in construction machinery, mainly used to remove air from concrete in construction, scrape the concrete floor, and increase the density and viscosity of concrete. Vibratory rulers are used in a wide range of applications. The vibrating ruler, also known as the walk-behind vibrating ruler, can be divided into gasoline vibrating ruler and electric vibrating ruler according to power. Generally, a vibration ruler of about 2 meters is used the most.

Screed Vibrating Machine,Concrete Road Paving Leveling,Concrete Paver Leveling

Vibropac Machinery Co.,Ltd , https://www.vibropac-power.com